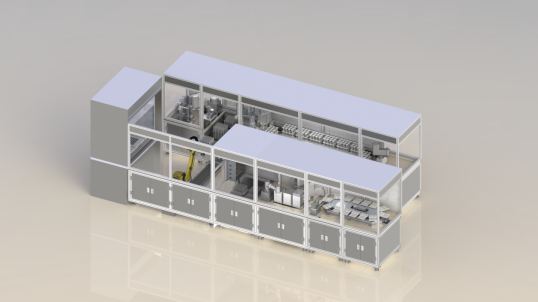

Model: YC-CPR

Tobacco chemical pretreatment robot is an unattended robot developed based on the standards of the Chinese tobacco industry. It can be used for the pretreatment of test samples such as nicotine, total sugar, reduced sugar, total nitrogen, chlorine, potassium, etc. for tobacco chemical indexes.It has brought innovation to the accuracy and efficiency of pre-processing of tobacco samples, and completed tedious sample processing work more efficiently, quickly and safely.One-click to realize the automation and intelligence of the entire test process, and at the same time, the system equipment status data and intermediate result data can be recorded and traced throughout the process, sample data can be imported, test results can be exported, historical data can be counted and queried, and user data and permissions can be edited.It can be set, with good user experience and operational convenience.

Tobacco chemical pretreatment robot can realize automatic quantitative weighing of tobacco samples, automatic quantitative weighing of potassium sulfate and copper sulfate, automatic addition of liquid (concentrated sulfuric acid and acetic acid), automatic high-temperature digestion, automatic extraction, automatic volume control, automatic shakeEven, automatic filtration, waste liquid collection, etc.

Tobacco powder loading robot

1. 42 or 84 sample sizes and weighing cup position can be selected

2. Each tobacco sample can achieve independent loading and effectively avoid cross-contamination of samples.

3. Roulette-style sample loading structure, saving space and facilitating the addition of tobacco samples

4. The robot automatically grabs the sample slot and weighs the cup to the sample weighing robot

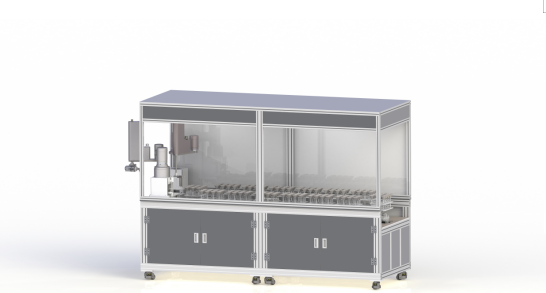

Tobacco sample weighing robot

1. Use METTLER high-precision balance to support samples of different weighing ranges and properties

2. Weighing accuracy:

Tobacco powder sample weighing range: 0.1000±0.0050g;

The weighing range of K2SO4 is 1.000±0.050g;

The weighing range of CuSO4 is 0.100±0.010g.

3. Sample weighing speed: ≤60 seconds/sample.

4. Can load tobacco samples into the bottom of the digestive tube

5. Teflon material with acid (concentrated H2SO4, acetic acid) liquid injection system, good safety and corrosion resistance.

6. The quantitative liquid addition and liquid extraction system adopts a high-precision liquid injection system, with an accuracy of up to 1%.

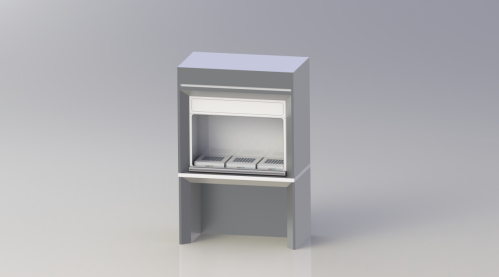

Dissolve robots

1. Program control automatically completes the digestion process

2. Achieve capping and effectively prevent the volatility of sulfuric acid in the digestion process

3. Install safety sensors, alarm notifications for risks and hidden dangers such as faults and temperature abnormalities during the experiment, and video monitoring of the entire process of digestion.

4. The ventilated kitchen automatically opens and closes the door, adjusts the air volume, and eliminates smoke and discharges it in time

Dingrong Robot

1. Use a high-speed vortex mixer to quickly mix the solution to prevent crystallization and precipitation.

2. Adopt a fixed capacity method based on machine vision image recognition to meet the fixed capacity needs of flexible and intelligent adaptive adjustment.

3. High-speed mixing equipment to achieve uniform and consistent sample concentration in the digestive tube.

Filtering robot

1. The liquid extraction and filtration system adopts a corrosion-resistant filtration and liquid extraction system, and the liquid extraction accuracy can reach 5%.At the same time, cross-contamination of samples should be avoided. If there are public cross-contact parts, they must be equipped with a cleaning system.

2. Automatic waste liquid pouring system to complete waste liquid collection and neutralization treatment.

3. The sample preparation is completed, the sample is loaded into the sample holder to be tested and wait for analysis.

software:

In conjunction with standard import templates, we realize one-click association intelligent export management for information samples, and freely set up export information templates.

Traceable requirements for experimental results

In addition to exporting the experimental results into information templates, they will be automatically saved in the database. The previous experimental results can be queried through sample numbers or test time at any time.

(1) The equipment system adopts touch control and visual interface design to display information such as equipment status, test stage and other information in real time;

(2) The current experimental samples can be automatically tracked in the software, and the experimental progress and test results can be obtained as soon as possible;

(3) Convenient to personal account permission management, distinguish between equipment administrators and experimental personnel, and prevent misoperation.

Tobacco chemical pretreatment process flow:

Tobacco sample digestion process: weigh tobacco powder → weigh copper sulfate → weigh potassium sulfate → load the powder into the digestion tube → quantitatively add concentrated sulfuric acid → digestion → fixed volume → mix well → filtration → pipetting → sample preparation is completed;

Tobacco sample extraction process: weigh tobacco powder → quantitatively add acetic acid → oscillation extraction → filtration → pipetting → sample preparation is completed